For over 3 decades NIC has delivered high quality component performance, and reliability to ensure successful deployment and operation of our clients’ mission critical solutions. We partner with clients as colleagues rather than contractors, trusted to perform like internal team members in responsiveness, dependability, and shared focus on achieving your goals.

We specialize in Lumped Component Filters, Cavity Filters, Ceramic Filters, Crystal Filters, Diplexers, Multiplexers, Integrated Microwave Assemblies, Phase Shifters, and VCTCXOs & TCXO晶振. NIC design and manufacturing headquarters are in Overland Park, Kansas, with additional manufacturing in Bhopal, India and Torrance, CA. NIC is certified as a Small Business, ISO 9001 accredited, AS9100 certified and has DoD Facility Clearance.

NIC is synonymous with reliability and high quality by virtue that our products are deployed in some of the most sophisticated and innovative military and commercial applications. NIC has implemented a formal Quality Management System (QMS) based upon and fully compliant with AS9100 and ISO-9001 standards, click here to see our certificate . This structure serves as a blue print for processes, continuous improvement initiatives, and corporate statement of commitment.

Management and personnel are specially trained and certified at all levels of operations to ensure that productivity, performance, and quality are maintained at the highest standards. Additionally, management is committed to continuous improvement across all functional areas of NIC. Examples include Lean Manufacturing to decrease cycle time, improve decision making, and maintain accountability throughout the organization. Statistical Process Control (SPC) is also used by quality engineers to monitor process variables and gain insight into production trends for each unique part.

We incorporate strategic disciplined processes to ensure that a specific, structured sequence of operations is completed to prevent potential quality problems. NIC’s QMS guarantees that processes from conception, design, development, production, and into final inspection are monitored with appropriate level of oversight.

Throughout our 37 years history, we have been awarded preferred supplier status by many customers for outstanding product quality and customer service. This success and the initiative to continuously refine products and processes is a testament to our entire organization’s commitment to provide our customers a cost competitive and high quality product.

NIC is fully compliant to the following quality and testing standards

-

-GENERAL TERMS AND CONDITIONS OF PURCHASE (Form-25)

-

-AS9100

-

-ISO 9001

-

-IPC-A-610 Certification for Inspections

-

-NIC Conflict Minerals Policy Statement

-

- MIL-STD-2000 - Certification for Soldering

-

-J-STD-001-A Certification for Soldering

-

-MIL-STD-105 - Sampling

-

-MIL-STD-45662 - All equipment calibration

-

-MIL-Q-9858A - Available for special contracts

-

-Department of State ITAR Compliant

-

NIC has established global manufacturing centers of excellence to provide cost-effective products with the highest levels of quality. Our integrated team approach including experts from disciplines ranging from engineering to manufacturing to quality ensures that NIC transfers value to our customer from design through volume production.

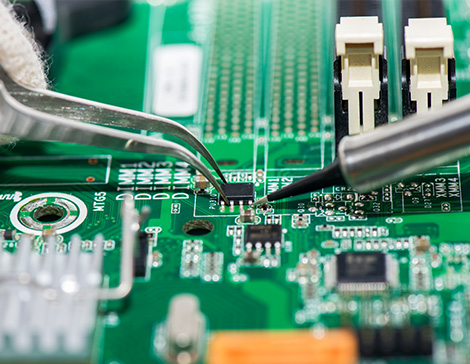

NIC is AS9100D and ISO 9001:2015 certified, and its facilities occupy over 20,000 square feet. We operate highly automated and dynamic assembly lines which allow NIC to monitor a wide variety of products in production at the same time. From special vision systems to automated test taking stations, solder reflow and crystal tuning to precise tooling in our own machine shop, NIC can produce efficient and high quality products for our customers.

NIC CRYSTAL has developed proprietary software to link analyzers to computer-driven automated test stations that require minimal operator intervention during final testing. This allows NIC to reduce cycle time and provide our customer real-time measured data.

NIC offers a wide variety of environmental testing capabilities in-house, which allows us to guarantee that quality and reliability meets the requirements of our customer’s application. NIC conducts 100% ESS screening on all products manufactured. Testing is automated to increase efficiency and ensure high performance in all conditions. Examples of environmental testing equipment include moisture resistance, temperature/ altitude chambers, thermal shock chambers, automated vibration system, and phase noise testing. The table below lists NIC's screening capabilities. Please contact NIC with your specific requirements.

手机版

手机版