石英晶体制造步骤概要

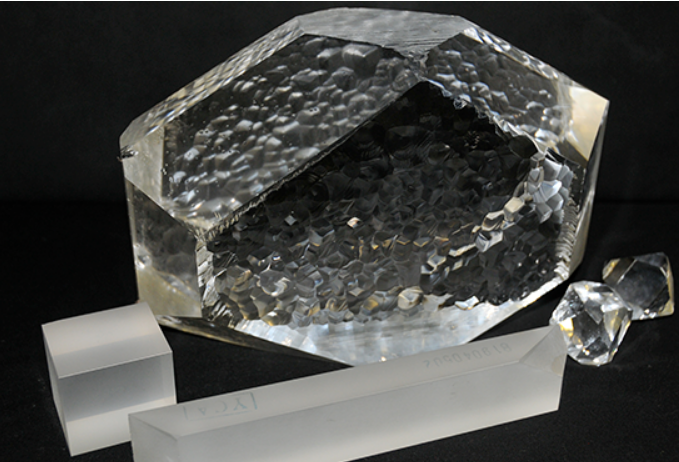

许多采购和工程都知道,经常使用的石英晶体原材料是石英和水晶,基本上都是采用人工培植的,原始形态就如同图中的水晶,无规则的菱形,需要用专门的工具和技术进行加工。第一步就是将石英棒切割成所需要的大小,以mm为计算单位,因为太小所以要计量精准,晶片的大小和厚度都要把握的刚刚好,以下是关于石英晶体谐振器和石英晶体振荡器生产的重要流程。

晶振的制造可分为四个部分:切割,研磨,整理和质量控制。

A.切割

切割操作是在石英棒上进行的第一个过程。用特殊的切片机将棒切成尺寸为1.27mm×1.27mm×0.04mm的小方形骰子。切割骰子的角度对于成品贴片晶振的整体性能非常重要。特殊的X射线单元用于确保相对于原子平面的适当切割角度。

B.研磨

从“母石”切下的石英骰子,称为“空白”,现在经过研磨精密研磨机。当晶体被研磨时,首先在一台机器上,然后在另一台机器上,实现在坯料主表面上逐渐更精细的光洁度。由于研磨操作减小了坯料的厚度,石英晶体谐振器的频率增加。对研磨机的适当控制将导致产生具有极其精确频率的晶体。

C.整理

在将石英坯料研磨至将产生所需频率的厚度之后,将它们彻底清洁并将金属电极真空沉积在它们的两个主面上。电极拾取存在于谐振器表面上的电脉冲并将它们引导至弹簧。反过来,弹簧拾取电脉冲,此外,还有助于将晶体支撑在其安装基座上。

安装音叉晶体后进行最终频率调整。在每个晶体上真空沉积附加金属。最后一步是通过将金属罐焊接到其底部来密封晶体,以保护易碎的坯料免受湿气,空气,处理等的损害。

D.质量控制

在过程质量控制中,在各种制造步骤中,确定有利的产量。在完成完成的装置之前,它们在质量控制站进行彻底测试,在最低-55摄氏度到+125摄氏度的温度范围内,最重要的是注意稳定的晶体频率。检查晶体的“活性”,因为它表明石英水晶振动子振动的强度,并且进行“泄漏测试”以确保晶体与其环境密封,以防止单元的劣化。

The manufacture of quartz crystals can be divided into four sections: cutting, grinding, finishing and quality control.

A.Cutting

The cutting operation is the first process performed on a quartz rod. The rod was cut into small square dice having a size of 1.27 mm x 1.27 mm x 0.04 mm using a special microtome. The angle at which the dice are cut is very important to the overall performance of the finished crystal. Special X-ray units are used to ensure proper cutting angles relative to the atomic plane.

B.Grinding

The quartz tweezers cut from the "mother stone", called "blank", are now milled with precision grinding machines. When the crystal is ground, a progressively finer finish on the major surface of the blank is achieved first on one machine and then on the other. Since the grinding operation reduces the thickness of the blank, the frequency of the crystal increases. Proper control of the grinder will result in a crystal with an extremely precise frequency.

C.Finishing

After the quartz blanks are ground to a thickness that will produce the desired frequency, they are thoroughly cleaned and the metal electrodes are vacuum deposited on their two major faces. The electrodes pick up electrical pulses present on the surface of the crystal and direct them to the spring. In turn, the spring picks up the electrical pulse and, in addition, helps to support the crystal on its mounting base.

Final frequency adjustment is performed after the crystal is mounted. Additional metal is vacuum deposited on each crystal. The final step is to seal the crystal by soldering the metal can to the bottom to protect the fragile blank from moisture, air, handling, and the like.

D.Quality control

In process quality control, advantageous yields are determined in various manufacturing steps. They are thoroughly tested at the quality control station before completing the completed device. At the lowest temperature range of -55 degrees Celsius to 125 degrees Celsius, the most important thing is to pay attention to the stable crystal frequency. The "activity" of the crystal is checked because it indicates the strength of the crystal vibration and a "leak test" is performed to ensure that the crystal is sealed to its environment to prevent deterioration of the cell.

手机版

手机版